We’ve released a major update to Nodi.

This update significantly expands Nodi’s DfAM (Design for Additive Manufacturing) capabilities. At the core of this release is the introduction of Implicit modeling.

With this feature addition, the following DfAM workflows are now possible:

- Stable generation of lattice structures such as TPMS

- Shape operations without worrying about Boolean, thickness, and fillet failures

- Control of internal structure and material properties based on analysis results

This article introduces the features added in this release and future prospects.

Addition of Implicit Modeling

While Nodi has previously supported modeling using curves, surfaces, B-rep, and Polygon Mesh, we’ve added Implicit modeling functionality in response to requests from the AM (Additive Manufacturing) field. This enables expression of complex shapes that were difficult to achieve with previously supported modeling methods.

We plan to prepare a separate article explaining the details and benefits of Implicit modeling and introducing examples.

What is Implicit Modeling?

Implicit modeling is a method of representing shapes using implicit functions.

Differences from Traditional Shape Representation

Traditional Polygon Mesh and B-rep directly describe shape boundaries (surfaces) using elements such as vertices, edges, and faces. This is called an explicit representation.

On the other hand, implicit function representation defines shapes not by directly describing boundaries, but by functions that determine whether any point in space is inside or outside the shape. This is an implicit representation.

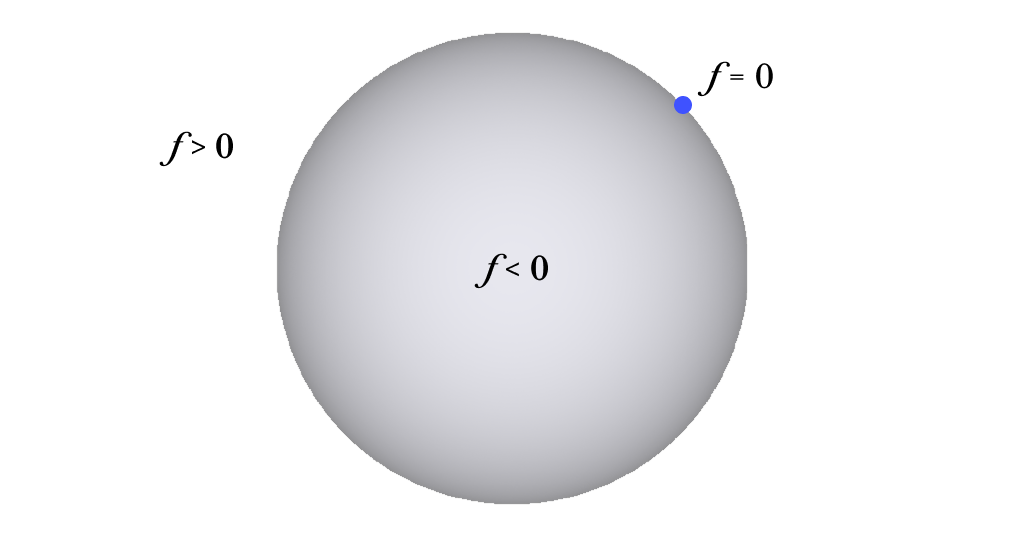

Specific Examples of Implicit Functions

For example, to represent a sphere with radius r using an implicit function, the function would be:

The value of this function indicates:

- Negative: point is inside the sphere

- 0: point is on the surface of the sphere

- Positive: point is outside the sphere

In this way, implicit function representation expresses shapes using functions that return “where a point is relative to the shape” rather than describing the shape itself.

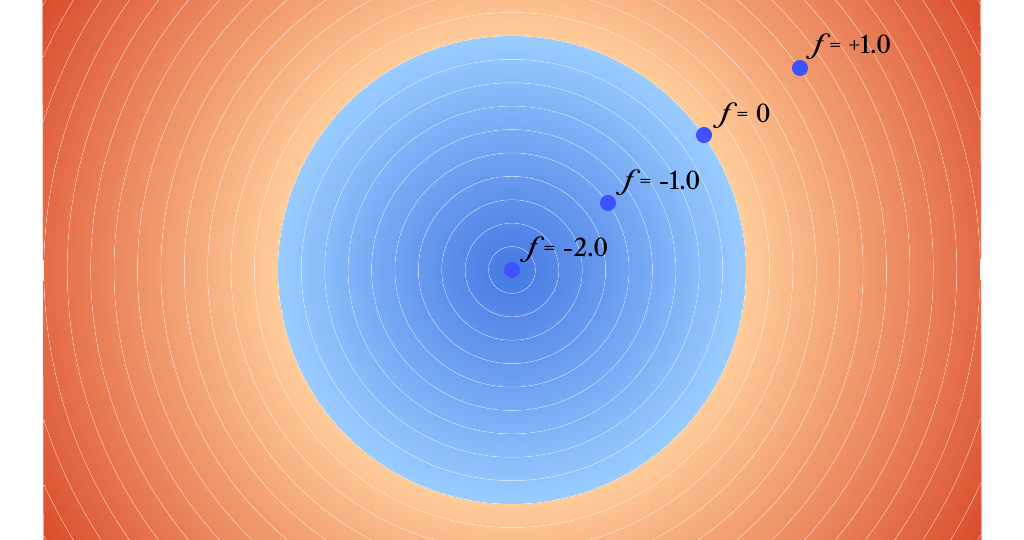

Furthermore, when the function value returns the signed distance from the boundary, it’s called a Signed Distance Function (SDF)1, and Implicit modeling realizes various shape operations using this signed distance. (The implicit function example for a sphere mentioned above also returns the signed distance from the surface, making it a Signed Distance Function)

A major advantage of this approach is that it enables robust realization of complex shapes.

- Lattice structures such as TPMS2 can be easily created

- Operations such as Boolean operations, fillets, and thickness can be realized much more stably compared to B-rep3

Due to these properties, Implicit modeling is highly compatible with approaches required in DfAM, such as lattice generation and internal structure design, as well as design methods that integrate with analysis.

Value of Implicit Modeling in DfAM (Design for Additive Manufacturing)

DfAM (Design for Additive Manufacturing) is a design approach that takes into account the potential and constraints of Additive Manufacturing. Specifically, it refers to designs that satisfy the following elements:

- Structured shape design (hollow, lattice, channels, etc.)

- Continuous control of thickness, density, and material properties

- Shapes based on analysis results

- Incorporation of printing constraints

To realize these elements during design, Implicit modeling is highly effective.

While traditional B-rep-based modeling had difficulty generating complex structures required in DfAM, Implicit modeling can handle them easily.

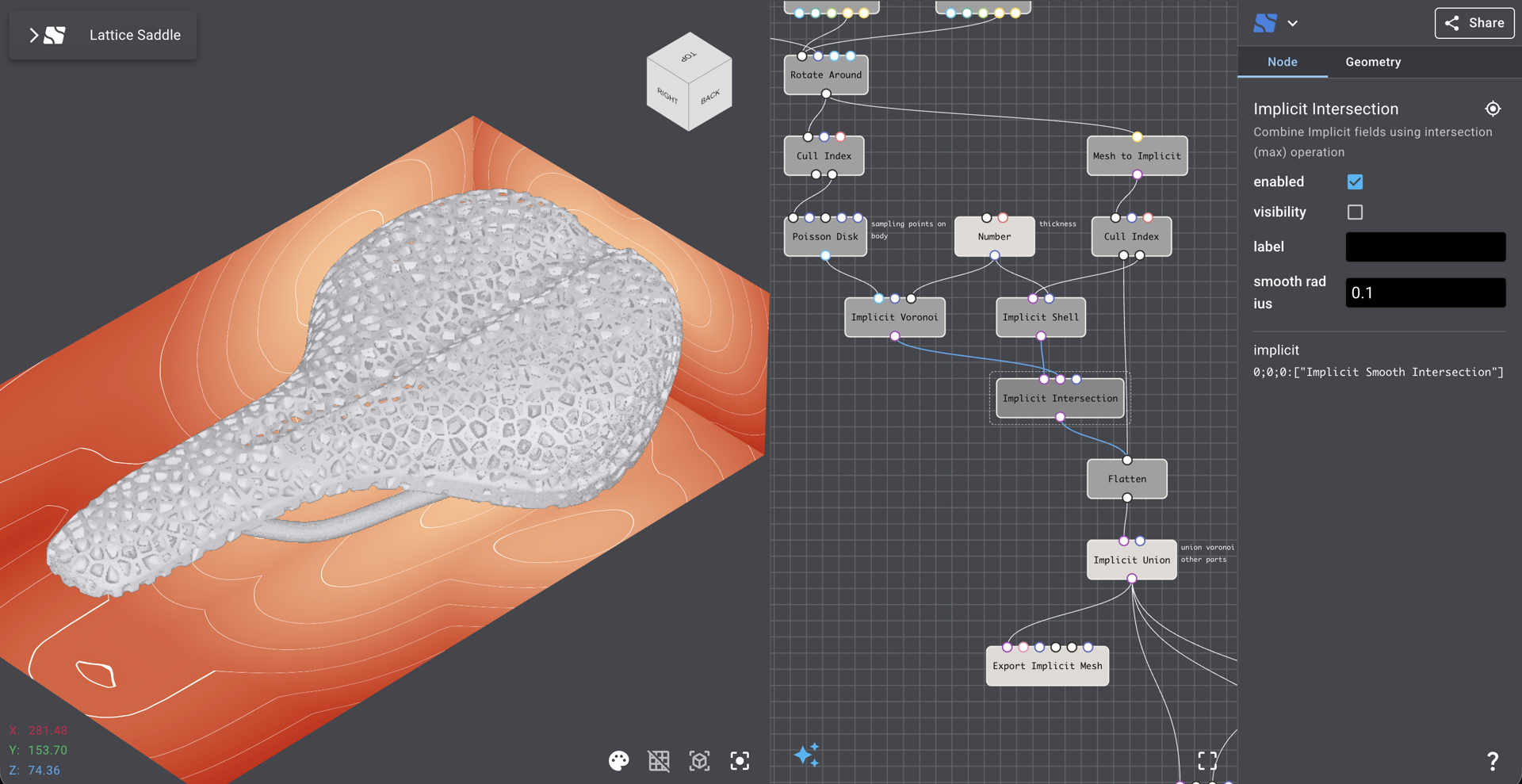

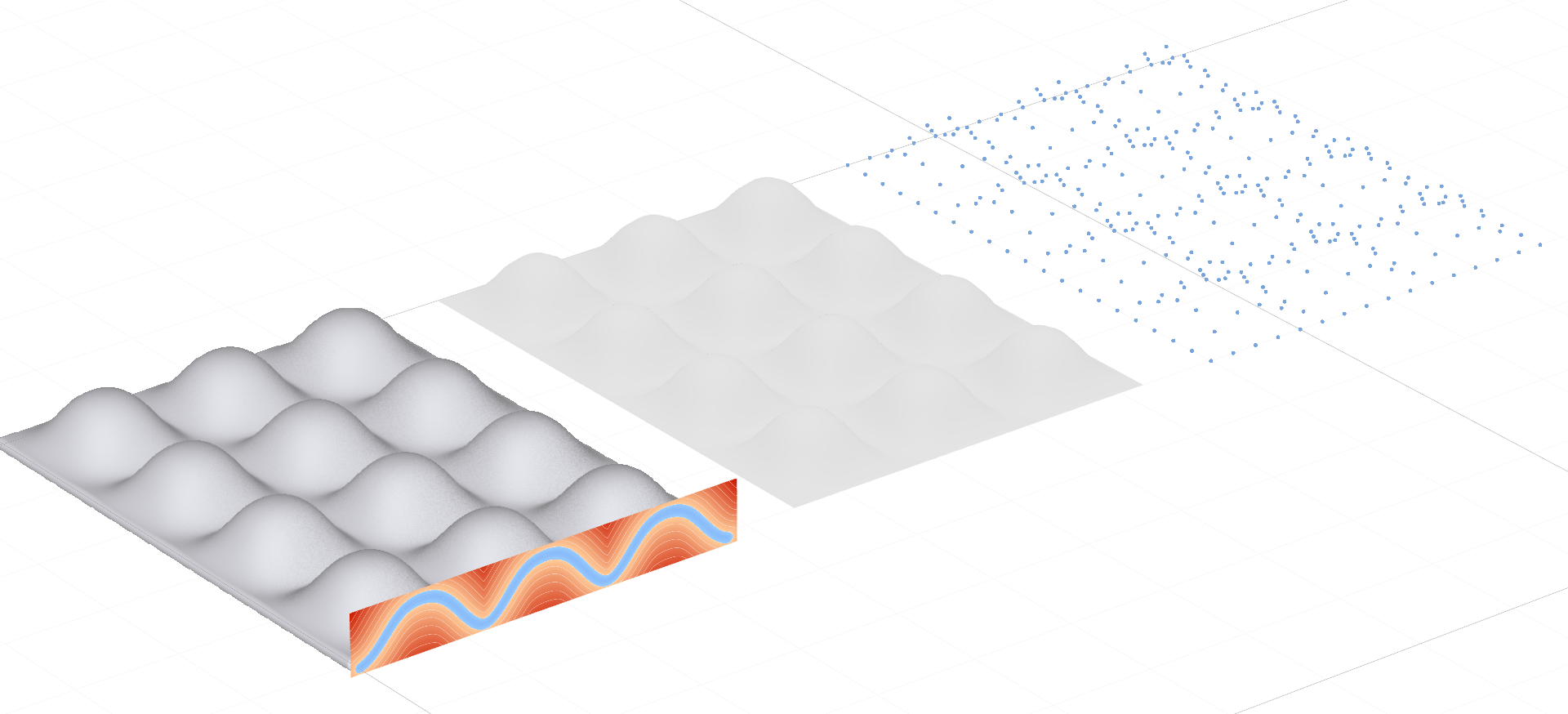

Example of Improved Rigidity by Applying Lattice to Thin-Wall Surface Structures

The following is an example of using Implicit modeling to generate a lattice on the surface of a thin-walled drone shell to improve rigidity.

This is an example of a 3D print where lattice structures were applied to the surface of a thin-walled drone shell, improving rigidity while minimizing weight increase.4 Even with the combination of thin shell + complex surface structure, Implicit modeling can generate stable results without failure.

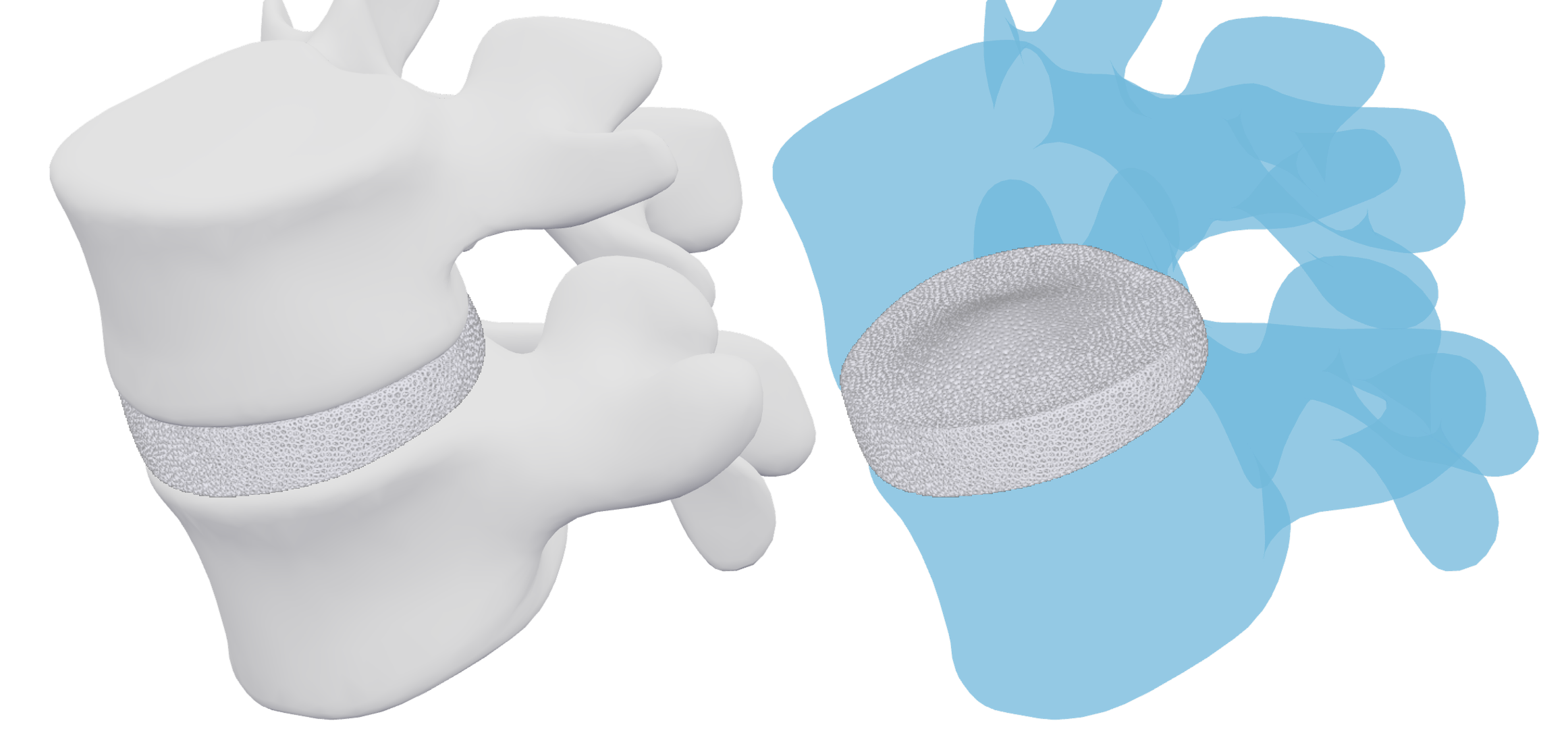

Lattice Filling and Material Property Control Through Analysis Integration

With this release, Nodi can now realize DfAM workflows that fill internal structures with lattices based on analysis results and control material properties.

Using this flow, you can achieve shapes with optimized material placement according to required performance. Nodi now enables designs that directly couple analysis results with geometry.

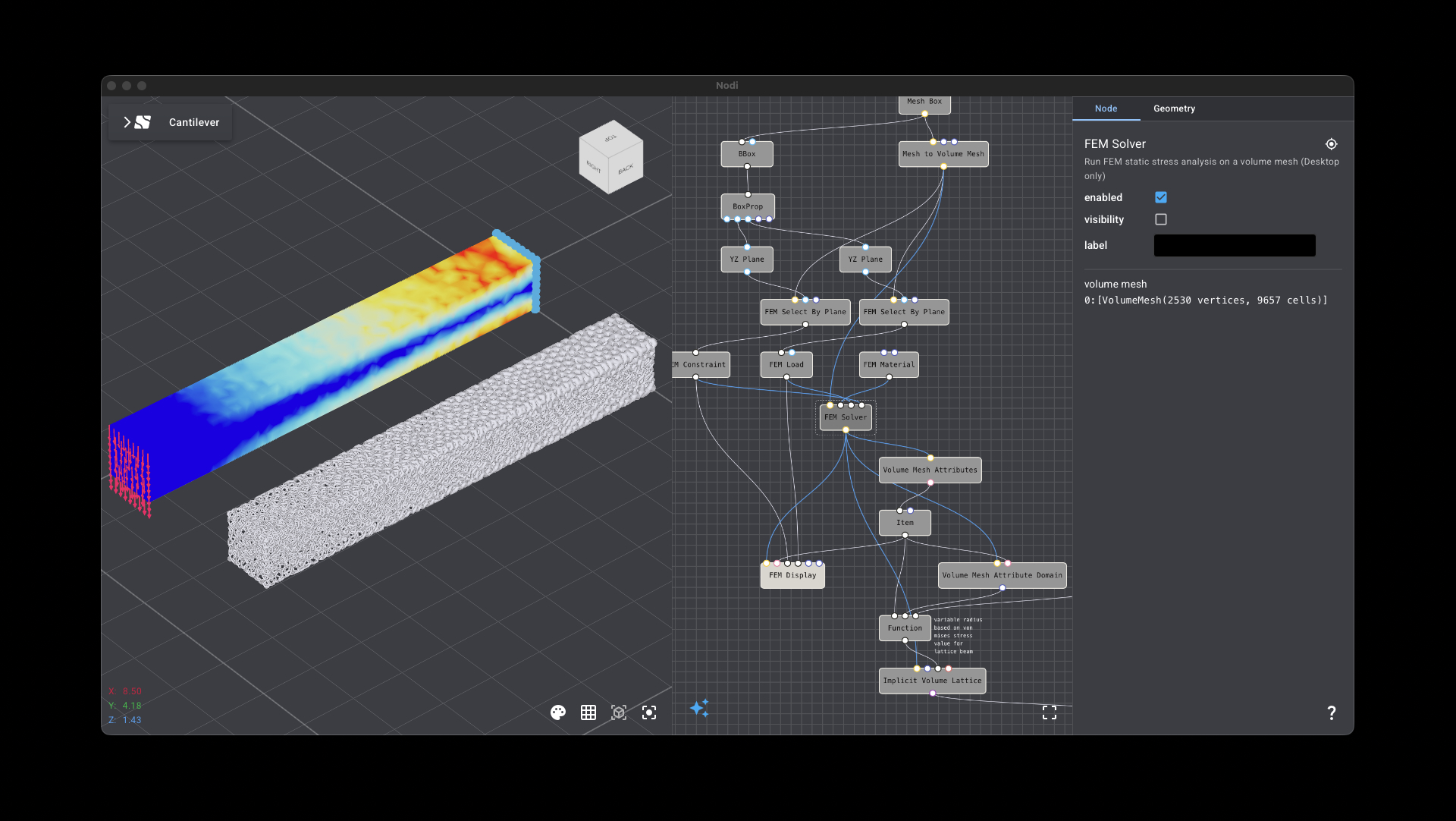

Development of Desktop Version

To handle heavy calculations involving analysis and increasing data volumes, we’re currently developing a desktop version.

The desktop version will enable direct execution of analysis from within Nodi.

By performing analysis setup and execution on the node editor, it becomes possible to perform analysis efficiently following procedural modeling workflows.

Also, since the desktop version is not constrained by web browsers, the following benefits are obtained:

- Ability to model larger shapes faster

- Realization of a design environment that works locally without network

While web browser applications inevitably have limitations on the performance they can deliver as tools, the desktop version can fully utilize local machine computational resources, significantly improving modeling efficiency.

Of course, we’ll continue to provide the web browser version as before.

If you’re interested in the desktop version, please register for the waitlist.

Register for Desktop Version Waitlist

Combined Use of Traditional Modeling and Implicit Modeling

Implicit modeling has the advantage of more robustly realizing processes that tend to fail in traditional B-rep-based modeling. However, it cannot completely replace traditional modeling methods. Each method has its strengths and weaknesses, and there are shapes that can only be expressed with traditional methods.

An effective approach is to appropriately combine both. By converting shapes created with traditional modeling to Implicit representation, it’s possible to leverage the strengths of traditional methods for shape design itself, while leaving processes such as Boolean operations, thickness, and lattice generation to Implicit modeling.

In this way, by switching modeling methods according to purpose, it’s possible to achieve both design freedom and processing robustness.

Other Updates

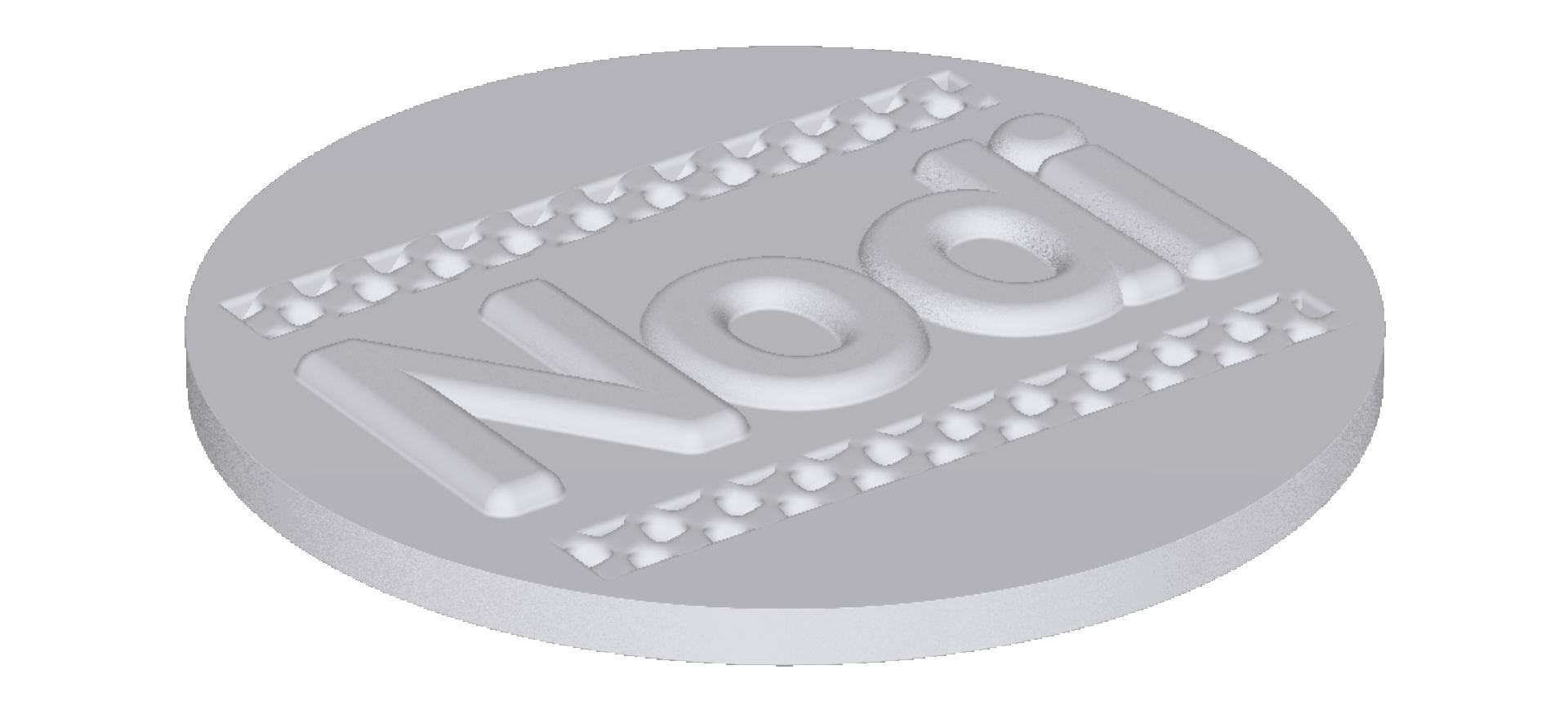

In addition to Implicit modeling, numerous other updates have been made, and we’ll introduce some examples below.

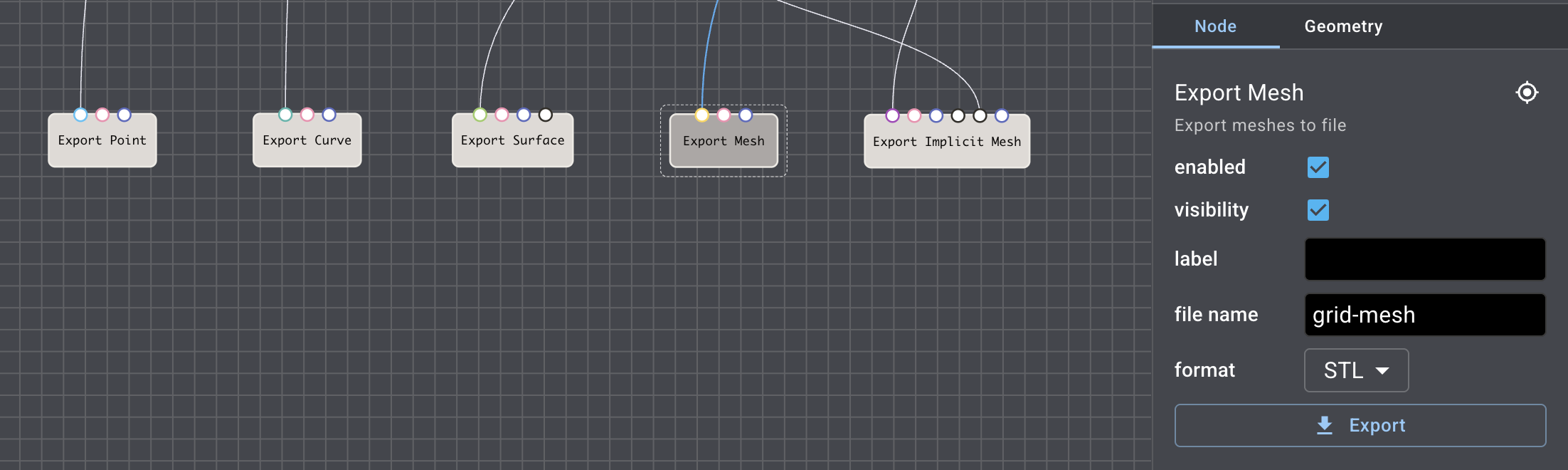

Addition of New Nodes

We’ve added many convenient nodes. In particular, nodes that support practical workflows, such as nodes for exporting geometric data, have been enhanced.

UI Improvements

We’ve also made several UI improvements. As one example, we’ve added type hints to node input/output ports. By color-coding the expected types for each port, it’s now immediately clear what kind of data should be connected during editing.

Conclusion

In this update, we’ve added Implicit modeling to Nodi as a core feature supporting DfAM-oriented design. We plan to gradually expand features necessary for DfAM while evolving into a more practical tool through collaboration with real projects.

Nodi can be tried immediately from a web browser without installation. The Implicit modeling and node-based workflows introduced in this article can also be experienced directly in the web version below.

We’re also currently developing a desktop version for larger shapes and analysis integration. If you’re interested, please register for the waitlist from the page below.

If you have feedback, requests, or would like to discuss collaboration regarding the tool, please feel free to reach out.

Footnotes

-

Inigo Quilez’s site https://iquilezles.org/articles/distfunctions/ is a good reference for examples of Signed Distance Functions. ↩

-

Abbreviation for Triply Periodic Minimal Surface, which, as the name suggests, refers to a continuous curved surface structure that repeats periodically in 3D space and has zero mean curvature (minimal surface). It has important properties from a DfAM perspective. ↩

-

For cases where Implicit modeling succeeds where B-rep fails, https://www.ntop.com/resources/blog/how-implicits-succeed-where-b-reps-fail is a good reference. ↩

-

The drone fabrication example was produced using MJF (Multi Jet Fusion) 3D printing in cooperation with YOKOITO Inc.. ↩